At Aprao we love standardisation. The prefabricated modular trend is just that: the standardisation of the construction process, carried out off-site in factory conditions. Prefabricated construction is used across all sectors, and with the cost of traditional construction methods rising, more developers are exploring prefabrication as an alternative - and it has an impact on how they manage their feasibilities.

Historically, construction has been a manual and fragmented process with multiple trades co-operating over a period of time to bring a build together - but when that process doesn't go according to plan, there are development projects that fall behind schedule and over budget. But in a controlled environment, the process can be completed in half the time of traditional construction methods.

The Effect on the Development Feasibility

1. Sales & Revenue

How is the revenue of a development scheme affected by modular construction? Some developers have come under scrutiny over the years for poor build quality. Prefabricated construction offers consistency, as well as the ability to create bespoke homes using design apps at speed. So you can decrease risk, while simultaneously driving the value of the development up, particularly when you can give clients the ability to literally design their own home using the technology that is now available to them.

The green revolution is happening, and consumers are willing to pay a premium for a reduced carbon footprint. Unsurprisingly, pre modular construction is eco friendly. It takes up to 67% less energy to manufacture a modular building. Furthermore, the units are far more energy efficient and ultimately result in cheaper running costs, helping the pockets of the purchasers!

On the downside, modular construction has a shorter life span than traditional construction. This could negatively impact the gross development value of a scheme. There are also question marks with the high street mortgage lenders. Will new build schemes be eligible for mortgages? Developers need to be confident that their buyers will secure a loan. This brings a substantial level of uncertainty to the exit strategy of a proposed modular development.

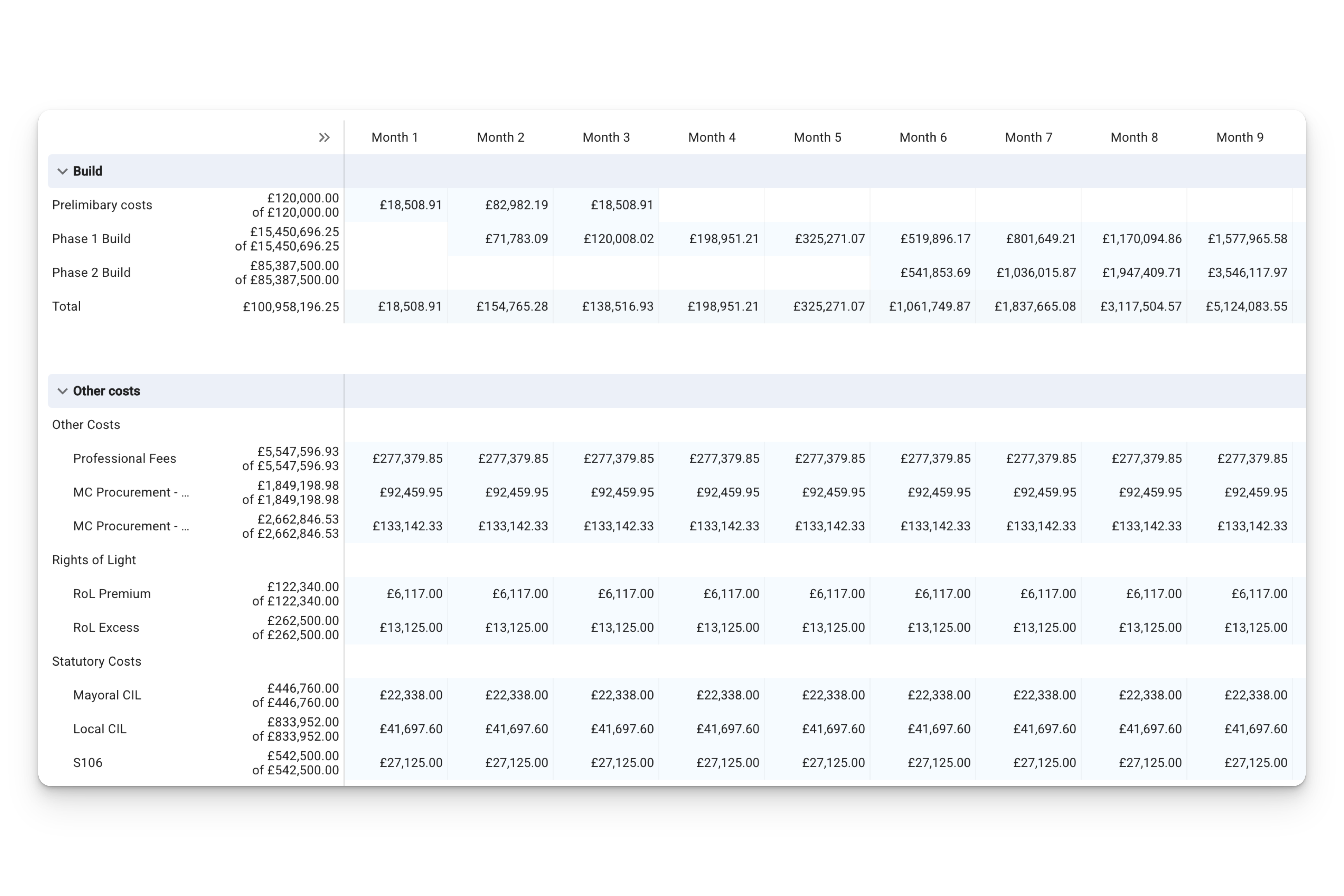

2. Build & Other Costs

It comes as no surprise that one of the biggest advantages about modular is that construction costs drop significantly. The costs can be between 10-35% less than traditional methods.

Modular is standardisation. Essentially, it is developing a streamlined process that can be repeated time and time again for each project. Once this is created, costs are saved through economies of scale and lowered design costs. Not only are the savings related to the hard construction, it also runs through to the associated professional costs.

Using modular construction methods also minimise disruption on site. The site is essentially cleared up until the point the modular units are delivered from the factories where they are assembled, and the disruption happens in one swift move. Having said that, detailed planning is essential. For example: access to the site is an important factor. A narrow muddy track may not suffice for logistics!

Despite these considerations a developer can reasonably assume a lower contingency on the build as most of the construction can be conducted off site with a higher degree of certainty. This will result in improved profit margins.

Economies of scale are an important consideration. Large developers can afford to establish their own manufacturing plants, and . We have heard that some contractors are even considering investing in their own plants. For SME developers considering modular to improve the bottom line, exploring joint ventures with modular specialists is a good entry point.

The Cash Flow

"Timing in life is everything."John Sculley, Ex CEO of Apple.

The same is applicable to property development. Modular construction, put simply, is much quicker than traditional construction methods. This affects the cash flow in a number of ways:

1. Sales of the completed buildings start much sooner

2. Construction timeframe is reduced, thus reducing project life span

3. Peak borrowing is reduced

4. Reduced interest costs on development finance

A recent study found that sales of completed units can start 30% earlier than traditional construction. This resulted in an increased developer IRR of 43%! The peak cash flow across projects was also reduced by 7% - while not quite as impressive, is still a significant gain.

What's next?

All indicators suggest that modular construction is coming into its heyday, in a perfect storm of increased environmental awareness, soaring demand, a desire for efficiency and personalisation, and of course, the technological advancements that enable all these elements to come together into a neat package that works for developers and consumers alike.

SME developers who work hard to retain their margins while exploring the new prefabricated options available to them, are liable to do very well despite the power of the bigger players - who have distinct advantages in terms of buying power, but are often less flexible, and lack the agility to quickly adapt to changing market conditions.

We're excited to see what the future holds for modular construction, and how this will be embraced by lenders and other financial stakeholders, particularly when it comes to being adaptable around insurance, ownership, responsibility and safety concerns - because it's clear to see that there are great benefits to be had by all vested parties, and those who do not adapt, could be left behind!

Leave a comment